Hysep® comprises a line of hydrogen membrane separation modules offered by TNO for evaluation purposes. The technology is based on thin-film palladium membranes which are capable of separating high purity hydrogen from a gas mixture.

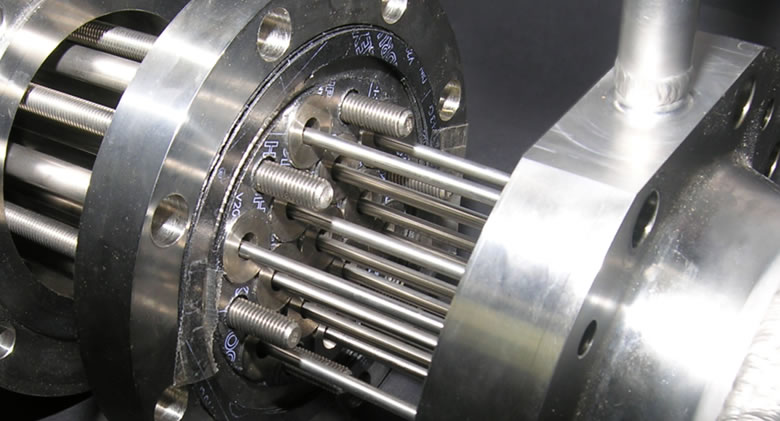

TNO receives regular requests for delivery of hydrogen membranes for purposes of evaluation. We deliver these membranes as a complete module. In this way the customer profits from the expertise TNO has acquired in design and construction of complete units and handling and sealing of membranes. Standardized Hysep© modules offer you the possibility to evaluate TNO’s high-performance hydrogen separation membranes. Tailor made modules can be delivered as well.

TNO has developed the Hysep® technology to enable low cost and reliable hydrogen separation based on thin-film palladium membrane technology. Modules can be used to gain experience using hydrogen separation membranes, to verify the performance of membranes in your specific application, and enable you to benchmark TNO’s membranes against alternative methods of hydrogen separation.

Potential applications of separation modules using TNO’s membranes include:

- Recovery of hydrogen from industrial process flows;

- Hydrogen purification for on-site production of pure hydrogen for industrial applications;

- Purification of hydrogen for use in fuel cells.

Into the future: integration of separation and reaction

Hysep® modules separate pure hydrogen from a hydrogen containing flow. In addition to the applications indicated above, where the only function is separation of hydrogen, future systems may offer integration of separation and reaction. Removing hydrogen as it is produced offers great benefits, for example in decreasing the operating temperature or the compactness of the membrane based process. Much research is going into application of membranes in the following reactions:

- Steam reforming

- Water gas shift reaction

- Dehydrogenation

Potential applications of membrane reactor systems include:

- CO2 removal by pre-combustion carbonization

- On-site hydrogen production (glass industry, food industry, electronics)

- Large-scale hydrogen production (e.g. for ammonia, refinery, …)

TNO was previously involved in a large European CARENA project which had a goal to promote the implementation of catalytic membrane reactors in the European chemical industry. Read more about CARENA project (428K)